PR

News

notice

Xcell Therapeutics opens doors to 62 countries with cell therapy clean culture technology

2021.10.19

Xcell Therapeutics opens doors to 62 countries with cell therapy clean culture technology

Serum-free cell growth conditions provide both 'safety and stability'

"Become a global company by developing next-generation cell therapy culture technology"

"Catch hair loss by planting grapevines at the roots of your hair?"

For the 10 million or so hair loss sufferers in Korea, this seems to be good news.

The root of the hair follicle, which holds the hair to the scalp, contains 'hair papilla cells' that look like a cluster of about 3,000 grapes.

When viewed under a microscope, their outline resembles a human nipple, hence the name.

Hair loss occurs when these cells, which draw nutrients from capillaries and allow hair to grow, fail to function properly.

The medical community has been focusing on root treatment for hair loss by multiplying these cells and transplanting them into hair follicle roots. In 2019, a Korean research team demonstrated the effectiveness of the treatment.

The question is whether it is possible to mass-produce enough human hair cells to meet the needs of 10 million people.

At this point, the decisive factor is the 'cell culture medium' that causes cell proliferation. If you search for 'medium' in the Naver English Dictionary, it is defined as 'a liquid or solid containing nutrients needed to grow plants, bacteria, or cultured cells'.

It's an unfamiliar term to the general public, but it's familiar to those who are even slightly interested in biology. It is often used as a textbook for elementary school students to learn about bacterial cultures.

In medical and academic use, cell culture media is a liquid nutrient solution that creates an environment for cells to grow outside the body in a way that is specific to each cell.

Recently, the market for cellular therapeutics, including human breast milk cells, has been growing rapidly.

Once degenerated or necrotic cartilage was the most active, but now research and development is being conducted in various fields.

As the market expands, the "small-scale industry" of materials, parts, and equipment for cell therapy development and production is also growing rapidly.

Among them, the media market, which is a core material, is gaining attention.

According to UK-based global market research firm Technavio, the market for cell culture media reached $3.674 billion (KRW 4.35 trillion) in 2020.

Technavio expects the market to continue to grow at a CAGR of 12.12% through 2025. By 2027, the market is expected to reach $8.72 billion (9.6 trillion won), according to this estimate.

The growth prospects will be exponential if cell therapy goes beyond hair loss or cartilage treatment and accelerates the development of "organ mimetic therapy" called organoids.

The biomedical industry is entering a new continent.

Xcell Therapeutics is a startup that has developed an innovative manufacturing technology for culture media, a key material for cell therapy. Until now, serum collected from animal or human blood was used to produce the medium, but it was difficult to extract and had limitations as a therapeutic agent.

Xcell Therapeutics produces media that does not contain any serum. We met with Dr. Lee Ju-yeon, head of the Life Science Research Center, who oversees technology development at the company, which is no longer considered a startup due to its performance and growth.

Q. First, please explain the properties and types of media, which are the company's flagship products, in a way that readers can understand. A. The medium is the rice of the cells, the food of the cells. Just as how far an electric car can travel depends on the performance of its battery, how far cells can proliferate depends on the efficacy of the medium.

Just as humans need to eat healthy food to be healthy, so do cells.

The coronavirus therapies currently being developed by several pharmaceutical companies, including Celltrion, are called 'antibody therapies', and the media used are focused on the production of antibodies.

Unlike antibody therapies, cellular therapies are not based on something that the cells secrete, but rather on the cultured cells themselves.

Because of this, it is important to culture the cells while maintaining their characteristics.

While both types of media feed the cells, the difference between antibody therapeutic media and cell therapeutic media is whether they contain ingredients that stimulate secretion, or whether the focus is on keeping the cells themselves healthy and maintaining the characteristics of each cell.

Q. Where is cell therapy at today? A. In the global market, the organoid market, which cultivates cells to create organ analogs, is growing. As of 2019, the market size was 77.75 billion won, and it is expected to grow by 20% annually.

Domestic cell therapy development is mostly focused on cartilage therapies.

There are still only five or six products that have received new drug approval and are being sold, but many companies are conducting clinical trials.

Recently, we are also conducting clinical trials of human milk progenitor cells, which will be a good news for hair loss treatment.

Our company is planning to release a human milk papilla cell culture medium for hair loss treatment and a keratinocyte culture medium for burn treatment by the end of this year.

Q, There are serum-free media, serum-free media, and chemotactic media depending on the ingredients, what is the difference? A. Antibody therapies, which have already entered the mature stage, began clinical trials almost 50 years ago, but they grew slowly and then experienced a rapid growth period with the advent of chemotactic media.

It was chemotactic media that enabled the mass production of antibody therapeutics.

A turning point was the advent of serum-free media.

In the past, the fetal heart of a cow was pierced to extract the serum and used as a medium additive.

This was called "bovine fetal serum medium," but it had a number of technical limitations, bioethical issues, and you could only get so much of it.

So a serum-free medium was developed that didn't contain serum.

However, the cells do not grow well without bovine serum, so human-derived materials are being used as a substitute for bovine serum.

A typical example is platelet concentrates. But human-derived materials have similar limitations to bovine serum: the possibility of viral contamination and limited production.

A further step up from serum-free media is chemically engineered media. They do not use animal-derived or human-derived substances, only synthetic or recombinant proteins.

For antibody therapies, chemotaxis has become the norm, while fetal bovine serum is still the predominant medium for cell therapies.

However, the global bio industry has recently begun to move away from fetal bovine serum media, and a variety of serum-free media are now available.

Large companies such as Thermo Fisher Scientific, a multinational bio company, are the main producers of serum-free media.

Chemical composition medium 'CellCor' raw materials are transparent and clean to prevent sources of risk such as infection

Q. What are the advantages of Xcell Therapeutics' media products compared to serum-free media?

A. We are focusing on developing media products for cell therapy drugs. Serum-free media on the market often contain human-derived substances such as platelet fractions or serum albumin.

This makes it impossible to eliminate the risk of contamination, including the possibility of viral infection from human derivatives.

The recent coronavirus pandemic has caused many disruptions in the supply of human-derived materials, especially platelet concentrates.

CellCor CD, a cell culture medium developed by Xcell Therapeutics in 2019 and launched last year, is a chemically composed medium that does not contain any unidentifiable ingredients such as animal- or human-derived materials, thus eliminating the risk of infection or physiological reactions.

In addition to safety, it also ensures production stability as there is no possibility of disruption in raw material supply due to pandemic situations such as Corona.

I can say that it has significant competitiveness not only in terms of medical efficacy but also in terms of industrial productivity.

Q. Besides the raw materials and ingredients of the medium, what other factors determine the competitiveness of your technology? To make a good medium, you need to know the cells well.

You need to be able to control the biopathology of the cells.

The raw materials for chemical composition media are similar to the nutrients that humans eat, such as vitamins and minerals.

Humans consume carbohydrates, minerals, vitamins, proteins, and fats through various foods, not just rice, and cells are similar.

The first is to provide the right balance of nutrients so that the cells can multiply sufficiently.

The second is the supply of cell-specific ingredients so that each cell can proliferate without losing its unique characteristics.

For example, in the case of burn cell therapy, a person with full-body third-degree burns needs to get a piece of their own skin tissue to make enough cells to heal the burns.

The most important thing is that the cells isolated from the patient's limited skin tissue are able to multiply in the culture medium to produce enough cells to make skin.

The next challenge is to ensure that the cells can be grown in culture and become part of the human body while retaining their unique characteristics, and that they do not develop side effects such as infection after transplantation.

To do this, we need to keep contaminants out of the proliferation process. With chemically composed media, you don't have to worry about this as much.

The competitive advantage is to use raw materials that are based on a thorough physiochemical understanding of the cells and that can be managed.

Q. Is the medium just used to quantitatively multiply cells, or can it functionally shape them or something like that? A. Both are possible. A typical "growth medium" is used to increase the amount of cells.

But it's a bit more complicated with stem cells, which can turn into many different types of cells, such as muscle or nerve.

The media used to turn stem cells into muscle or nerve cells are called differentiation media. There are a number of functional media that do this.

Q. How much demand is there for your media in the domestic medical market, and how are you planning to expand into overseas markets? A. Currently, there is a lot of demand for clinical trials, but it is difficult to estimate exactly how much demand will be generated in a certain period of time because the amount of demand can vary greatly when the product is sold as a post-clinical treatment.

As not only stem cell but also immune cell media are being developed, I think the market has the potential to grow considerably in the future.

Especially in the case of chemically composed media, there is no other company in Korea that has similar technology to ours, so the domestic market is highly regarded for its growth potential.

However, ironically, our company started with overseas markets,

The domestic technology development capability is not inferior to the world level, but in the case of media, domestic buyers have strong stereotypes and prefer overseas products.

Therefore, we import more than 90% of raw materials and auxiliary materials for the development and production of therapeutics from overseas such as the U.S. and Europe. However, due to the corona crisis, the supply of media and resins, which are core materials for the bio industry, has been disrupted.

Unlike in Korea, overseas markets such as China and Europe have a high level of trust in 'Made in Korea' products.

As a result, our company was recognized and entered the overseas market first.

In fact, not only in the biomedical field, but also in the semiconductor and display fields, it has been a long-standing practice to import and use Japanese products for certain materials and components.

Then, in 2019, Japan's export restrictions on materials, parts, and equipment became an emergency.

Since then, the localization of major materials and components in the IT sector has been radicalized.

The recent coronavirus outbreak has caused material supply problems in the bio industry as well, but we expect the domestic market to expand significantly once the localization of core bio technologies is in full swing.

Expanding to 30 international distributors by 2023, building distribution hubs in Asia and Europe

Q. Please introduce your overseas export performance in more detail.

A. Once a medium is selected as a therapeutic ingredient, it is not easy to switch to another product, and product loyalty is quite high.

Globally, there are only two chemically composed media for mesenchymal stem cells: Excelsior Pharmaceuticals' products and Japan's Ajinomoto (味の素).

When the Yongin plant in Gyeonggi Province is expanded later this year, it will have the capacity to produce 255,000 liters per year with a cGMP (Current Good Manufacturing Practice) rating recognized by the US FDA.

Since the successful R&D of chemical composition (CD) medium in 2019, we have completed two years of technology verification with a multinational company through active technology promotion and product promotion marketing activities.

Before entering the global market, we signed a 'white label' contract with an American company to supply as an OEM.

The CD badge product was launched in earnest in the second half of 2020, and is currently scheduled to be sold in 62 countries by signing distributor agreements with 10 influential distribution companies in Germany, India, Southeast Asia, and China.

We aim to expand to 15 distributors by this year and 30 by 2023.

We also need to secure a smooth logistics chain in preparation for the increasing demand for our products in the global market, so we are considering establishing distribution hubs in certain regions.

We are currently in discussions with companies in Singapore in Asia and Hungary and the Netherlands in Europe to establish distribution hubs.

Q. Can cell culture technology be used in other areas besides therapeutics? A. The most prominent application outside of therapeutics is cultured meat.

Alternative meats are processed from soy and other plant-based ingredients, while cultured meats are made by growing cells to produce meat.

Cultured meat is primarily made from muscle, fat, and nerve cells.

Muscle stem cells are isolated from muscle tissue of cows, pigs, and chickens to increase the amount of cells and turn them into muscle cells using differentiation medium to make cultured meat.

Currently, we have a strategic investment (SI) relationship with DAESANG Corporation to jointly develop cultured meat. We are developing two types of media: a 'proliferation medium' for muscle stem cells and a 'differentiation medium' that can turn stem cells into muscle.

Q. Tell us about your awards and investments.

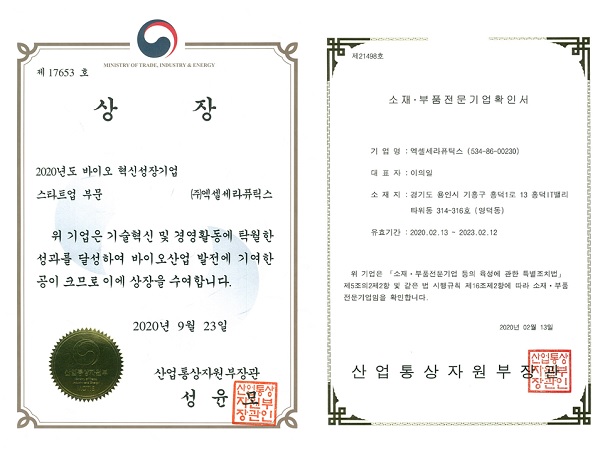

A. In 2020, we received a ministerial commendation from the Ministry of Trade, Industry and Energy and were certified as a bio company specializing in material parts. We became a "small business certified company" as expressed by the media. We were also selected as a "preliminary unicorn," a national project for venture powerhouses, by the Ministry of SMEs and Startups. Thanks to our high scores in government and overseas market evaluations, we received KRW 20 billion in Series A investment in October 2017 and KRW 33.6 billion in Series C investment last March.

Our major institutional investors include Korea Investment Partners, KDB, Korea Development Bank, Small and Medium Business Bank, and more than 10 other companies.

Q. It seems that you can develop more advanced products for therapeutics, but how far can you go technologically?

A. The medium for stem cells has been commercialized in earnest, and the medium for keratinocytes on the skin and hair cells that can be applied to hair loss have been developed and will be released later this year.

Going forward, our first goal is to increase the pipeline of various cell media.

By 2023, we are preparing to launch media for immune cells such as NK (natural killer) cells and T cells, which are being actively researched as immuno-oncology or immunotherapy drugs.

Furthermore, we aim to grow into a company like Lonza, the world's No. 1 bio contract development and manufacturing organization (CDMO), based on our deep understanding of cells and technology.

Source: https://www.mk.co.kr/news/it/10041607